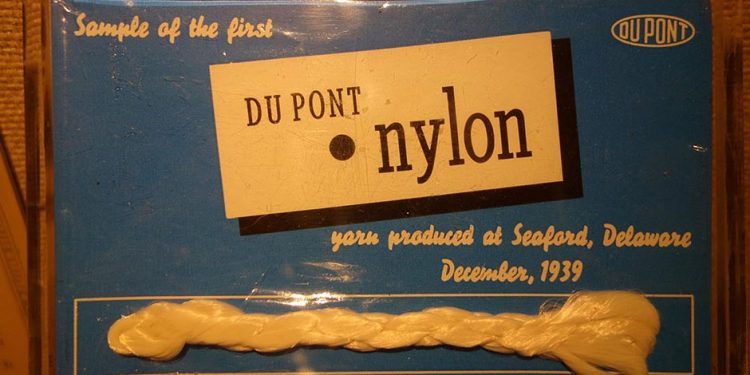

Over the years, carpets and rugs have been woven and tufted using wool, silk, cotton, sisal, seagrass and more. But around the turn of the 20th-century, a new fiber, made by man, was introduced into the carpet industry. It all started when Wallace Carothers of DuPont produced new synthetic polymers on February 28, 1935, called nylon fiber. The word nylon denotes a family of synthetic polymers that is one of the most commonly used. Carothers' discovery was one he made while he was attempting to create a viable substitute for silk. Because silk was used during World War II to make parachutes, flak vests, vehicle tires, and more, there was a dearth of silk. A happy consequence of Carother's achievement is the fact that nylon is recyclable. Nylon Types In actuality, Carothers came up with two types of nylon.

They were:

Type 6

- less expensive than other polymers

- extremely resilient

- color-fast

- recyclable

- increased open molecular structure

- readily dyed

Type 6,6

- more difficult to dye

- more expensive

- tighter molecular structure

- recyclable

- extremely flexible

- excellent color-fastness

Twisting Nylon yarn comes in a single strand, 2-ply twisted strands, and 3-ply twisted strands. The most common nylon yarn is the 2-ply. Then the fiber is twisted 2.75 times per inch and up to 7.5 times per inch. Higher twists result in the following characteristics:

- better tip definition

- less bulk and softness

- higher performance

- more bulk and softness

- limited tip definition

- lower performance

- Continuous Dyeing is a technique that permits the application of dye to the carpet in open-width form under the dye applicator. This allows for tinting an endless amount of carpet that has been sewn end to end. This method is used most often for residential carpets.

- Solution Dyeing is accomplished by extruding synthetic yarn from a colored solution. The filament is saturated with the dye. This action ensures that the color is outstandingly colorfast.

- Beck Dyeing refers to the method that colors carpet by placing it in a generous vat, or beck, of dye. Usually, floor coverings dyed in this manner are supersaturated with deep, vibrant color.

- Printing is the application of dyeing matter onto the face of the carpet through the use of screens, inkjets, or rollers. This type of coloration is used mostly for area rugs and commercial carpeting.

- Space dyeing is a variety of coloring that prints different hues along the length of yarn before it is made into carpet. This procedure is used for "fleck" carpeting and allows for range dyeing after it is tufted.

- Yarn dyeing is done in one of four different methods:

- pad dyeing

- stock dyeing

- jet dyeing

- skein dyeing